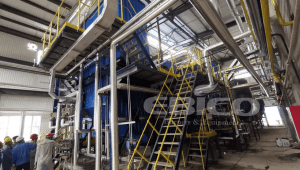

Laos DONGYAN PETROCHENICAL 35-ton Steam Boiler Supporting Low-nitrogen Burner Project

Laos DONGYAN PETROCHENICAL 35-ton Steam Boiler Supporting Low-nitrogen Burner Project

LAO-CHINA DONGYAN PETROCHENICAL CO.,LTD is a sino-foreign joint venture oil refining and chemical enterprise, which is held by Yunnan Overseas Investment Co., LTD., and jointly invested by Laos National Petroleum Corporation, Laochina-China Joint Investment Co., LTD., and Yunnan Dongyan Industrial Co., LTD. Recently, the Laos Vientiane Refined Oil Refining Project (LAO-CHINA DONGYAN Refined Oil Refining Project) jointly invested and operated by Laos and China has been put into operation.

LAO-CHINA DONGYAN Refined Oil Refining Project will become the largest and only large-scale energy production enterprise in Laos after its completion. The project mainly uses petrochemical intermediate raw materials such as naphtha, catalytic and coking, and direct diesel oil imported from abroad to Vientiane, Laos. So that to refined production of gasoline, diesel and related derivative by-products, and mainly sells and strategic reserves in Laos. The fuel requirements of the project are specific and strict. The main fuel of the boiler is the fuel gas produced by the refinery and the diesel for vehicles, and it can be switched between single and mixed combustion modes. According to the unique needs of customers, EBICO adapts the EC12GGQR type burner to the 35-ton steam boiler, and adopts the combustion mode of the two-channel (vehicle diesel/fuel gas) burner to solve the problem of single burning and burning switching.

The latest low-nitrogen burner of EBICO EC series is a low-nitrogen and energy-saving product with the latest international cutting-edge technology successfully, which is developed by EBICO. It adopts the combined application of appropriate amount of super-mixing, vacuum internal mixing, subsonic and other technologies. Thus, it is possible to stably control NOX emissions within 30mg/m3 without FGR. This series of burners also have a hot-air type series, and the main engine can enter hot air below 250°C, which fully meets the low nitrogen requirements such as thermal oil furnaces.